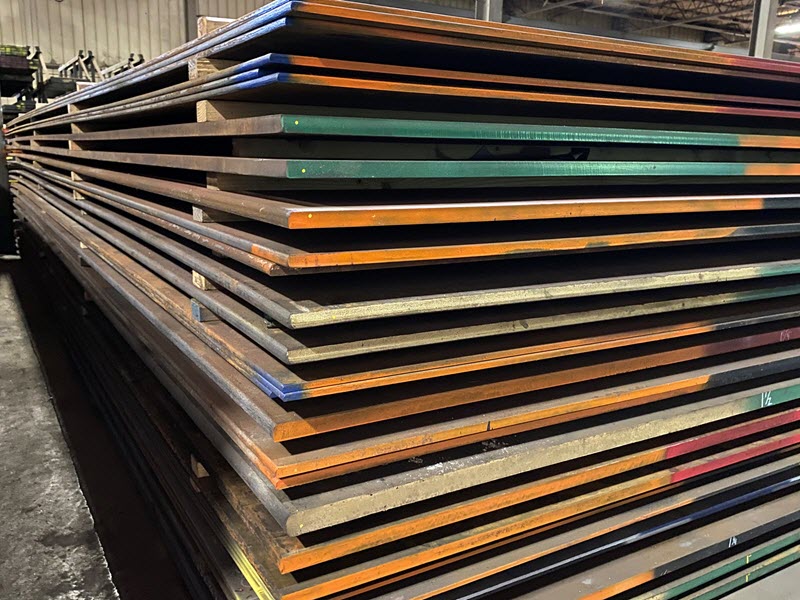

Wear Resistant Steel Bucket Liners

Ford Steel provides AR steel bucket liner fabrication services to a wide range of industries. Utilizing Wearalloy 400, 450, 500 and Nickel Chrome Plus Plate (A-572 and A-514 are also available), Ford Steel can fabricate wear resistant steel bucket liners for loader, excavator, dragline, and shovel buckets.

BENEFITS OF AR STEEL BUCKET LINERS

Buckets suffer a tremendous amount of abrasion which leads to a rapid depreciation of an investment that should provide centuries of reliability. Unfortunately, loader buckets can retire quickly from being cracked, worn, and severely damaged due to the lack of the buckets being adequately protected. One of the most cost-effective and quickest way to extend the bucket's life is investing in wear resistant AR steel bucket liners. Benefits of AR steel bucket liners include:

- Longevity of loader buckets and excavators

- Greater carrying capacity for more weighted products

- Reduces sliding and movement

- Cost-efficient

WEAR RESISTANT BUCKET LINER OPTIONS

Wear resistant steel bucket liners can take heavy blows without the risk of deformity or damage. In severe applications such as loader buckets, AR steel is more suitable because of the steel's high-grade alloy coating such as nickel and carbon that creates stronger corrosion and wear-resistant. AR steel has no fixed chemical formula, it is created and sold depending on the hardness range needed for each application. Several options for AR steel bucket liners include:

- AR400 wear-resistant steel bucket liners offer four times the longevity that other steel plates with a tensile strength of 180 200 ksi.

- AR450 is the sweet spot of wear-resistant steels that is thin and lightweight without sacrificing tensile strength.

- AR500 is not as flexible in forming shapes as AR400 and AR450, however, it is the highest lightweight tensile strength abrasion resistant steel.

The most common steel liners used in bucket liners are AR400, because of its flexibility, and AR500, because of the high tensile strength. The wear-resistant steel liners prevent any bulk material from contacting the base metal, eliminating the risk of exposure to elements that can cause corrosion or damage. Ford Steel’s AR steel bucket liner fabrications are joined together by a unique interlocking design that makes changing liners quick and easy. AR steel fits tightly onto the non-flat or warns surface of the bucket reducing material carry-back and sticking. Clean buckets ensure that the operators use the bucket to its full capacity of the loader reducing downtime of clean-up and reducing waste of materials.

INDUSTRIAL APPLICATIONS

Abrasion steel is found in several industries such as mining, earthmoving machinery, heavy ware platforms, industrial hoppers, funnels, and feeders. Ford Steel specializes in AR steel bucket liner fabrication, plates, sheets, and coils. As the leading international metal manufacturer, we pride ourselves in providing the highest quality steel that exceeds the longevity and protection compared to our competitors at a competitive price. Our team of highly trained representatives and experienced engineers are here to help find you the best wear-resistant steel bucket liners option (AR400, AR450, AR500) that fits your bucket liner.