Abrasion Resistant Steel Hopper Liners

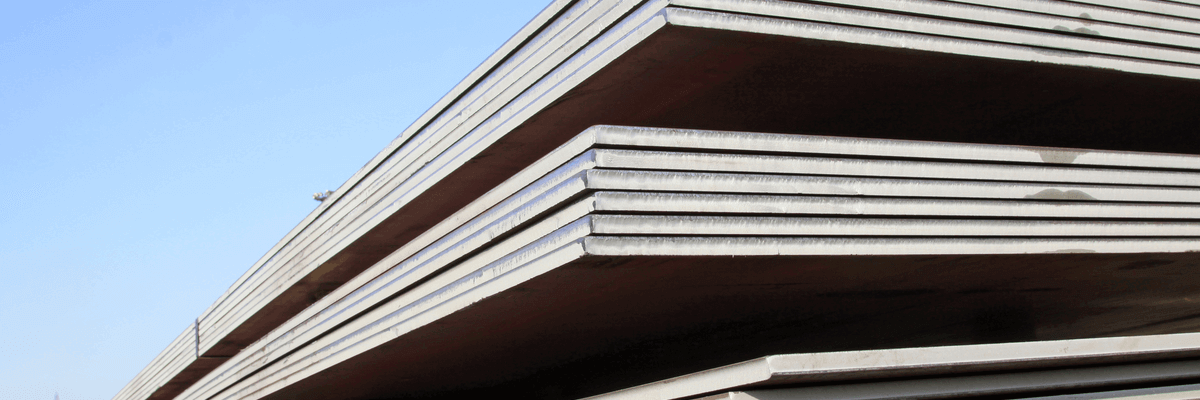

Ford Steel can cut to size bolt-in or weld-in liners for chutes, hoppers, and transfer points. We provide abrasion resistant steel hopper liners and wear resistant chute liners to a wide range of industries.

MATERIALS HANDLING WITH AR STEEL HOPPER & CHUTE LINERS

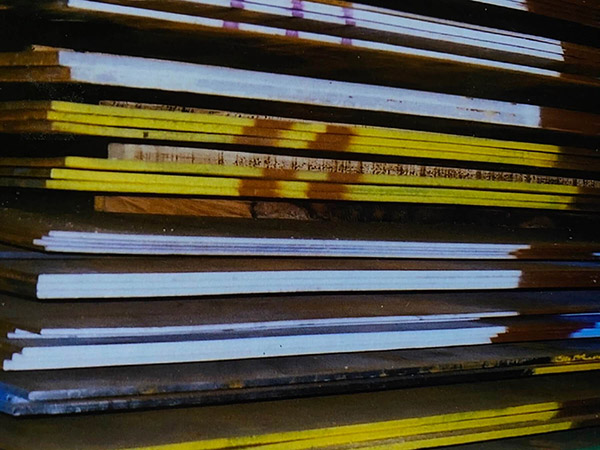

It is vital for industries to successfully transfer material especially maintaining the functionality of chutes such as the lining in them. Investing in high-quality liners protects the chute from damages, maintain workflow, increase productivity, and less downtime. Abrasion resistance (AR) steel is proven to be the ideal solution when corrosion resistance and wear resistance is essential. Abrasion resistant (AR) is a high quality of steel that is impact-resistant, heat, and corrosion resistant. At Ford Steel, we house a selection of AR steel hopper and chute liners from AR400 to AR500.

LONGEVITY

Abrasion resistance steel hopper liners are designed to withstand beyond normal conditions and last longer than standard steel. Wear resistant chute liners are cost-efficient by providing excellent protection such as corrosion resistance and increasing the longevity of your chutes. Depending on the hardness needed for the application, typically AR400 and AR500 are more common in chute hopper liners. Choosing the right liner for each specific chute design maximizes material transfer and the overall efficiency of the system, reducing the buildup of products, efficient flow, and dust suppression.

APPLICATIONS

AR steel chute liners are versatile, they can be cut to fit tighter spaces but still maintain their strength and durability. Each abrasion resistant steel hopper liners are strategically placed and bolted throughout the liner to prevent holes or weak spots in the chute hopper. The alloy coating on AR wear resistant chute liners eliminates materials sticking or blocking the flow of materials. Ford Steel engineers analyze each chute to ensure the fabricate and install streamline the workflow from when the material leaves the pully head to the despot onto the receiving conveyor is smooth and reliable.

WHY FORD STEEL?

Abrasion wear resistant chute and hopper liners are reliable and dependable when it comes to safety for personnel and teammates. Each AR steel product from Ford Steel is designed for quick change-out and easy replacements to increase uptime with little to no downtime. As the leading steel provider nationwide, Ford Steel houses a variety of shapes, sizes, and thicknesses to fit every unique job.

We provide the best abrasion resistant steel chute hopper liner solutions that exceed the life of your chutes and hoppers at a competitive price. We stand behind our wear resistant steel products to meet and exceed as the highest quality steel manufacturer in the industry.