AR Steel Cutting Edges

Ford Steel is known for our weld-on, bolt-on, and slip-on custom wear resistant cutting edges available from Wearalloy 400, 450 or 500 steel. We offer straight, spade nose or duckbill design edges. Ford Steel fabricates cutting edges perfectly suited for your specific AR steel cutting edge application. With years of experience under our belt, the team at Ford Steel has the high-quality equipment and well-trained staff needed to complete your next project.

WEAR RESISTANT CUTTING EDGES

Ford Steel values customer satisfaction which is why we work our hardest to ensure you get the most out of your custom wear resistant cutting edges. Properly maintain your machine's cutting edge system ensures high productivity, less maintenance downtime, and less stress during operations. No matter how large the machine, we have you covered for the right part at the right price.

We know all machines do not have the same parts which are why our warehouse is fully stocked with numerous AR steel and wear resistant parts. As a major primary source of metal products in the United States, Ford Steel houses a various range of custom wear resistant cutting edges and end bits: shanks, blades, plow bolts and buts for excavators, graders, bulldozers, teeth, ripper tynes, and other machines that can withstand extreme conditions.

Our products are of the highest quality material made from heat-treated, quenched, tempered, and through-hardened steel alloy with a hardness range of 400-500 Brinell to reduce maintenance and prevent abrasions. Some of the custom wear resistant cutting edges we perform include:

LOADER CUTTING EDGES

We offer AR steel cutting edge services that are available for all applications such as wheel loaders, excavators, loader buckets, bucket liners, chutes, and hoppers. Custom design or standard

- Drilled for segments and adaptors

- Bolt-on and Weld-on adaptors

- Heat treated for long life

- Spade nose

GRADER CUTTING EDGES

Grader blades are chosen based on two specifications: heat treated grader blades and black high carbon grader blades. Heat-treated grader blades are boron steel that is through hardened to a hardness of 420-512 Brinell compared to standard high carbon steel that has a hardness of up to 320 Brinell.

Heat-treated grader blades

- Double beveled curved:

- Double beveled flat:

- Overlays and underlays

- Ripper tynes and teeth

- Serrated

Black high carbon graders blades

- High-level performance

- Strict quality control

- Cost-efficient

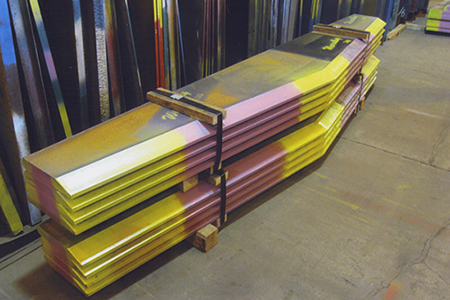

BULLDOZER CUTTING EDGES

With over four decades and counting, Ford Steel has partnered with numerous companies as a primary source manufacturing parts for tractor blades and bulldozers. We have a complete range of thickness in both heavy-duty and standard blades. Our hot cupped AR steel cutting edges and end bits protect your machine from damage by providing maximum penetration resistance.

CUSTOM DESIGNS

Can’t find the part for your unique machine or have a non-traditional bucket? Not a problem! At Ford Steel, we can modify an end bit or cutting edge from its standard specifications to fit your unique AR steel cutting edge application. In the event we do not stock a particular part, we order a tailored solution from our manufacturing facility saving you research and downtime time.

Our team of specialists is dedicated to delivering custom wear resistant cutting edges and bits product solutions at a competitive price. Our overall goal is efficiency, we attend your site to perform inspections on your systems to evaluate their condition and recommend solutions that improve the longevity and performance of the machine.

INDUSTRIAL APPLICATIONS

Abrasion steel is found in several industries such as mining, earthmoving machinery, heavy ware platforms, industrial hoppers, funnels, and feeders. Ford Steel specializes in AR fabrication, plates, sheets, and coils. As the leading international metal manufacturer, we pride ourselves in providing the highest quality steel that exceeds the longevity and protection compared to our competitors at a competitive price. Our team of highly trained representatives and experienced engineers are here to help find you the best wear-resistant steel bucket liners option (AR400, AR450, AR500) that fits your application.